49151 Concrete Durability Design Report

- Subject Code :

49151

- Country :

Australia

Instructions

Students must complete this Assessment Task 3 individually

This Assessment Task 3 requires a report to be produced

Reports will be checked for plagiarism

The layout of the report shall comprise the following sections:

o Cover Page

o Table of Contents

o Introduction

o Durability Characteristics

o Material Specifications

o Supplementary Cementitious Materials

o Design Life

o Conclusions and Recomendations

o Bibliography

The total length of the report must not exceed 14 pages (inclusive of Cover page and Bibliography, exclusive of Appendix).

Students are required to use high quality referencing sources available in the UTS library such as textbooks, online databases, electronic journals and online standards

Students are required to use the APA or Harvard style of referencing

Students should refer to following website link for assistance in the write up of their report:

https://www.uts.edu.au/current-students/support/helps/self-help-resources/typesassignments/reports

Submission Details

Each student must upload a soft copy of the report by PDF version (i.e., Assessment Task 3) to UTS Canvas using the Turnitin Assessment link that is available under the subsection heading Reports under the Assignments Section in UTS Canvas by the due shown below.

If there are any issues with the report, please contact the subject coordinator (paul.thomas@uts.edu.au). Due date of Assessment Task 3: 11:59 pm Wednesday 3/05/2023

Late submissions will receive a penalty of 10?duction in marks per day the report is late for a period of 7 days only. Please contact the subject coordinator (paul.thomas@uts.edu.au) for further instructions on how to submit a late report.

The Project

Sydney Metro is revolutionising public transport in Australia and concrete is making it happen, as shown in Fig. 1. The $8.3 billion project is a revolutionary computer operated driverless train public transport system connecting the North West of Sydney. The work will commence on the manufacture of precast concrete segments which will line the inside of the new metro tunnels. Concrete is selected as the construction material after careful consideration of the visual impact of the structure on its service environment. Construction material providing graceful curves, appealing form, and durable robustness is required for this Sydney Metro tunnel structure.

Concrete provides the above advantages for the construction of metro tunnel. As each boring machine advances, it places precast concrete tunnel lining segments in its rear position to shore and line the excavated rock. The lining concrete segments are grouted into positions providing the structural stability, soundness and waterproofing to the inside tunnel space.

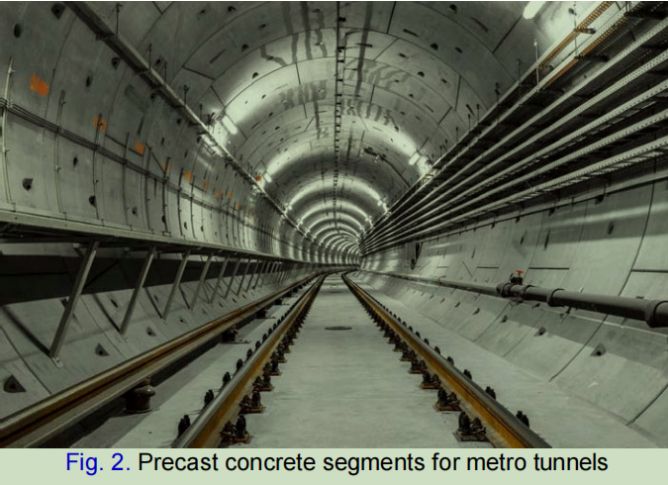

Automated computer operated driverless trains require a dependable, waterproof, stable tunnel configuration and it is the concrete segmental tunnel lining that makes the metro tunnel work and it is the precast concrete that delivers this in style, as shown in Fig. 2.

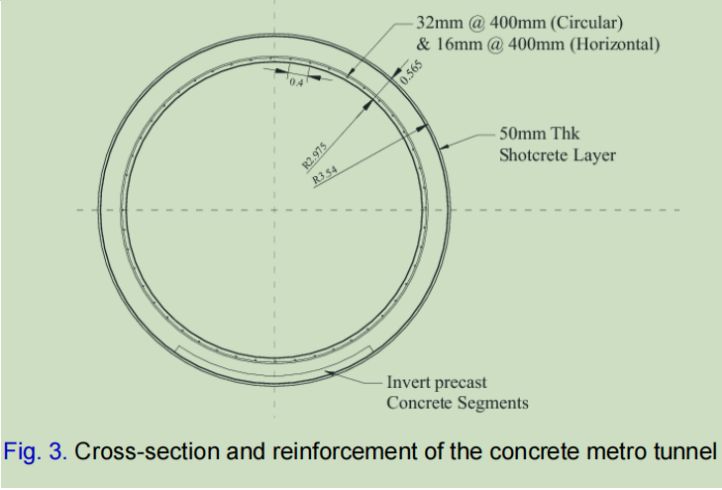

Precast concrete segments will be used in this new metro tunnel structure in SydneyThe cross-section of this tunnel is shown in Fig. 3.

The internal and external radiuses are 2.975 m and 3.54 m, respectively. There are both circular and horizontal reinforcements. At the external surface, there is a 50-mm thick shotcrete layer.

Typical precast concrete segments manufactured in factories, which may be used for Sydney Metro tunnels are shown in Fig. 4.

A similar structure located nearby constructed 50 years ago, showed map pattern cracks of concrete, surface spalling, and steel corrosion, as shown in Fig. 5. These cracks and deteriorations may be due to alkali silica reaction (ASR), sulfate and acid attacks, and corrosion due to chloride ion penetration in this coastal area.

Students are expected to complete a report presenting the design of a concrete mix that meets specifications. Topics to be covered in the report include:

? Time-dependent deformation behaviours and durability

? Methodology, analysis and synthesis to provide conclusions and recommendations

Students will analyse and solve a real-world concrete mix design scenario that meets strength, durability, and serviceability specification requirements in order to demonstrate design-thinking and decision-making methodologies. As a Civil Engineer for the project, you are required to produce a report that incorporates the concrete mix design, curing, strength,

Time-dependent deformation, long-term durability, serviceability, and material specifications. Based on the existing concrete mix design in the previous Assessment Task 2 with characteristic compressive strength of 55 MPa and a minimum slump of 120 mm, the following requirements have to be further and considered and met in this concrete durability design:

(1) Identify the functional role of raw materials and apply this knowledge to mix design philosophy and attributes relating to achieve the necessary integrity, serviceability, and durability requirements.

(2) The tunnel is located in a coastal area containing sewage and chemical materials. For this new tunnel, to improve the durability and resistances to aging and deterioration identified in Fig. 5, what are the main considerations in your mix design for the precast concrete segment?

(3) Special attention needs to be paid when placing the concrete with heavy reinforcement arrangement involved in the components of the structure.

(4) A design life of 100 years is expected of the structure. In relation to durability comment on the type of cement used and aggregates selected, typical concrete cover to reinforcement and tendons need to be specified. Suggest a method to estimate the design life of the structure for the concrete cover chosen based on steel reinforcing corrosion.

(5) Prepare a material specification for the precast concrete segments considering long- term serviceability and durability requirements in the coastal area.

In writing your report, ensure that you have addressed the criteria of points (1) to (5) above.

Note: Standards Australia does not have a specific guidelines for tunnels. In NSW, TfNSW has a specifications for tunnels (TN 004: 2019) which references specifications outlined in Engineering Specification SPC 301 Structures Construction. SPC 301 specifies RTA QA Specification B80,"Concrete Work for Bridges" and uses the specifications of AS 5100.5 Bridge Design Part 5: Concrete. You will use the AS 5100.5 to design the materials required for a 100 year design life.

Marking Scheme

The breakdown of the marks associated with Assessment Task 3 is shown in the assessment criteria below. The marks awarded for this Assessment Task 3 is based on clear communication and presentation of the project intensions, the assessment of the criteria for the project and the summary and conclusions. The structure of the marking scheme mirrors that of Assessment Task 2.

Assessment Criteria

Identify and justify appropriate strategies to solve the problem

Correctness and justification of solution to address the problem

Identify and locate knowledge to address the problem

Structure (10 marks)

1. Table of content with proper formatting 3 marks

2. Paragraph, figures and tables with proper formatting 4 marks

The format for all paragraph, figures and tables must be same through the whole assignment

The figures and tables must be correctly numbered

Content (90 marks)

1. Introduction 10 marks

Outline the scope of the report and introduce the report objectives

2. Environmental Exposure and Durability Issues 10 marks

Identify the exposure environment and use AS3600 and AS 5100.5 to specify design classifications.

3. Raw Materials, Materials Specifications and Mix Design 30 marks

Identify the functional role of raw materials and apply this knowledge to mix design, serviceability, and durability requirements.

Fresh and Hardened Properties

Briefly identify the requirements of the concrete for placement.

Address specifications for hardened properties.

Discuss concrete curing for the precast segments.

Prepare a material specification for the precast concrete segments considering longterm serviceability and durability requirements in the coastal area.

4. Design life 20 marks

Outline necessary steps to achieving a design life of 100 years. AS 3600 covers concrete structures, but only provides design life specifications for 50 years. AS 5100.5 covers concrete for bridges, but does provide a design life for 100 years. AS 5100.5 is usually specified when a design life greater than 50 years is required for a structure.

Discuss design life in relation to durability comment on the type of cement used and aggregates selected. Typical concrete cover to reinforcement and tendons needs to be specified. Suggest a method to estimate the design life of the structure for the concrete cover chosen based on steel reinforcing corrosion.