Risk Assessment & Quality Management in Project Management

1. Executive Summary

The company AusManufacturing Pty Ltd specialising in the manufacture of vinyl flooring, which had already dominated a rather large market share, deals with the problems connected with the stock at Zmart Pty Ltd retail stores in Sydney, Perth, and Melbourne. In this case, factors such as a clash of the self-interest of a supplier and a retail chain, risks associated with the management of the inventory, supply chain problems, and operational problems are also discussed. Though there are challenges, such cooperation with a focus on situational skills has led to the development of possible solutions to address inventory control to increase operating performance.

2. Analysis

2.1 Main Risks of the Project Case Study:

- Inventory Overstock: As highlighted earlier excess inventories are one of the major risks with implications in the broad financial and operational activities of concern organizations. They result in additional storage costs, handling difficulties that complicate the process, possible product deterioration, and the managerial inability to use the money that bound for other valuable use (Hasbullah, 2020).

- Conflicting Interests: This is a major risk because Zmart and AusManufacturing have some differences in their perception of the best course of action regarding IM strategies. Zmarts strategy includes reducing warehousing costs and maximizing space for the products as much as possible. On the other hand, AusManufacturings strategy is to ensure product availability and avoid a shortage of stocks to meet the required demand (Lewin, 2011).

- Supply Chain Disruptions: This leads to problems with stock availability and longer lead times when delivery takes longer, especially when transporting the closely located inventories. Either products are out of stock or there is an overstock of inventories because the flow of products does not replenish on-time forecasts or is disrupted by events that could not have been predicted (Ivanov, 2017).

2.2 Risk Management and Supply Chain Standards:

- Inventory Management Techniques: This is particularly important as the clients will be able to enhance on various methods such as (JIT) and VMI systems as far as inventory management is concerned. While JIT cuts down on inventory, by controlling production to match consumption, VMI enables one to assess inventory needs using current sales figures (Danese, 2012).

- Collaborative Planning, Forecasting, and Replenishment (CPFR): CPFR involves some degree of communication, particularly in the area of sales forecasting, promotions, and inventory disposition among supply chain partners. One is to facilitate timely business decisions in an aim to have an appropriate stock to match with outlooks.

- Supply Chain Risk Management Frameworks: Great attempts have been made to develop frameworks like Supply Chain Operations Reference (SCOR) model that can give a standard methodology to analyse the supply chain risks and develop necessary risk control mechanisms (Ho, 2015).

3. Identify, Assess, Manage, and Control Risks Identified

3.1 Key Issues and Risks:

- Inventory Overstock: The main concern is having too much inventory at Zmart's location, which can result in higher storage costs and the risk of products becoming obsolete.

Solution - Implement VMI System:

o Identifying the Risk: Having excess inventory ties up capital and increases holding expenses.

o Assessing the Situation: Conduct a thorough analysis of current inventory levels and past sales data to identify products that are not selling well.

o Managing the Situation: Set up a Vendor Managed Inventory (VMI) system with Zmart, where AusManufacturing keeps an eye on inventory levels and replenishes stock based on agreed triggers and sales forecasts.

o Controlling the Situation: Schedule regular review meetings to adjust replenishment schedules based on changes in demand and seasonal patterns.

Conflicting Interests:

o Identifying the Risk: There may be differences in inventory management goals and strategies between Zmart and AusManufacturing.

o Assessing the Situation: Conduct a stakeholder analysis to understand the priorities and concerns of each party regarding inventory management.

o Managing the Situation: Establish a joint steering committee with representatives from both companies to facilitate agreement on inventory management strategies.

o Controlling the Situation: Develop a collaborative agreement that clearly outlines roles, responsibilities, and performance metrics to ensure mutual understanding and alignment.

Supply Chain Disruptions:

o Identifying the Risk: Lengthy delivery times and transportation inefficiencies that affect inventory replenishment and customer service levels (Tomlin, 2011).

o Assessing the Situation: Conduct a root cause analysis to identify bottlenecks in transportation logistics and supply chain operations.

o Managing the Situation: Explore options to optimize transportation routes, consider alternative modes of transportation, or establish local distribution centers closer to Zmart's location (Bugert, 2018).

o Controlling the Situation: Develop contingency plans and establish key performance indicators (KPIs) to monitor transportation performance and address delays promptly (Caro, 2018).

3.2 Actionable Plan:

- Inventory Overstock:

o Identifying the Risk: Excess inventory increases holding costs and the risk of products becoming obsolete.

o Assessing the Situation: Analyze historical sales data and current inventory levels to identify slow-moving products.

o Managing the Situation: Implement a VMI system with Zmart to monitor inventory levels in real-time and automate replenishment based on agreed triggers.

o Controlling the Situation: Conduct regular inventory audits and adjust replenishment schedules based on demand forecasts and seasonal variations.

- Conflicting Interests:

o Identifying the Risk: Misalignment between Zmart's focus on minimizing storage costs and AusManufacturing's priority of ensuring product availability.

o Assessing the Situation: Conduct a stakeholder analysis to understand the objectives and concerns of each party regarding inventory management.

o Managing the Situation: Establish a joint steering committee with representatives from both companies to promote collaboration and decision-making.

o Controlling the Situation: Develop a collaborative agreement that clearly outlines roles, responsibilities, and performance metrics to ensure mutual understanding and alignment.

- Supply Chain Disruptions:

o Identifying the Risk: Lengthy delivery times that impact inventory replenishment and customer service levels.

o Assessing the Situation: Conduct a comprehensive analysis of transportation routes and logistics to identify inefficiencies and bottlenecks.

o Managing the Situation: Explore options to optimize transportation, such as using faster shipping methods or establishing local distribution centers.

o Controlling the Situation: Develop contingency plans to mitigate delays and establish KPIs to regularly monitor transportation performance.

By proactively addressing these risks through effective risk management strategies and collaborative efforts, AusManufacturing Pty Ltd can improve inventory.

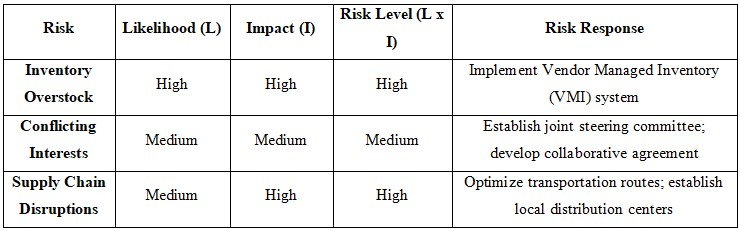

Risk Matrix table:

Are you struggling to keep up with the demands of your academic journey? Don't worry, we've got your back!

Exam Question Bank is your trusted partner in achieving academic excellence for all kind of technical and non-technical subjects. Our comprehensive range of academic services is designed to cater to students at every level. Whether you're a high school student, a college undergraduate, or pursuing advanced studies, we have the expertise and resources to support you.

To connect with expert and ask your query click here Exam Question Bank