Structural Steel Design for High-Rise Buildings CIVL4020

- Subject Code :

CIVL4020

Steel is one of the most basic construction materials in use today and has had a significant impact on the look and feel of the cities of the world. For these reasons, construction of high-rising, bridges and other industrial structures is inconceivable if steel does not present an incredible set of characteristics. This material is ideal in structures where high strength-to-weight ratios, toughness, durability, and flexibility are desirable due to different loads and environmental conditions. Of these attributes, one could mention that to them it is related that steel has remained the material most used in the construction of big and complicated premises and operatives, particularly in such instances when height contributes another factor for example in the building of tall buildings and bridges. In a design that incorporates the use of steel, the engineer has the benefits of working with steel in so many forms. Concrete is the superior material in areas of compression only, while steel is equally good in compression as well as tension and therefore well suited to carrying diverse types of loads. It is for this reason that today, steel has been adopted for designing the primaries of most new-generation high-rise frames that facilitate thinner and lighter walls and floors, and result in the openness of interiors that define most modern architectural structures. In this project, the idea is to retrofit a six-story commercial building from a reinforced concrete structure to a steel structure. The adopted systems for concrete construction were initially based on pure, practical advantages inherent in the material: high compressive strength, but with limitations of heavier mass per unit volume and restricted variability of form. Transitions to steel have several benefits including improved capacity, better design freedom, decreased mass, and higher efficiency. Through the application of steel not only it is possible to create thinner and lighter buildings but at the same time get the possibility of either increasing its height up or improving its loading capacity without undergoing major changes to the base and other critical parts of the building (Foraboschi, 2020).

This project focuses on the design of two crucial structural components: An interior steel column and an interior steel beam observed in the six-story building. These elements must have met certain Structural Code in AS 4100-1998 Australian Standard for steel design of buildings. This standard covers what may be among the most significant parameters of steel structures such as strength, serviceability, buckling, and stability of individual members within the structure. The importance of adhering to such regulations is critical for the realisation of the project's structural safe outcomes and the durability of the building (Franklin, 2019). These elements must adhere to the guidelines provided by the Australian Standard AS 4100-1998, which outlines the structural requirements for steel design in buildings. This standard governs important aspects of steel structure design, including member strength, serviceability, buckling resistance, and stability. Ensuring compliance with these regulations is essential to meeting the projects goals of structural safety and longevity (Franklin, 2019).

1.Why Steel?

Comparing Steel with other construction, materials, particularly concrete, the following benefits can be gleaned: Based on some of the characteristics of steel discussed above probably one of the important factors that made me decide to use steel in this project is that this material has the best strength to weight ratio. From a tensile force-resisting point of view, beams that have to bear bending moments and columns that have to bear compressive forces use steel. Compared with the former, concrete demonstrates high compounding strength but low tensile strength, and for enduring tensile forces, it generally must be reinforced with steel rods or barbs, also known as rebar. The result is higher overall performance without additional complexity by using only steel material.

A third major benefit of steel is its durability. Steel is resistant to various factors such as Fire, Corrosion, and even different forms of weather. Protective coatings in todays era can further reduce the corrosion of steel in outdoor or humid environments which would be highly valuable in todays high-rise buildings construction. In addition, due to its ductility, steel can sustain permanently a certain deformation when subjected to axial force rather than brittle failure under extreme loads, such as earthquakes or high wind loads. This ductility is one of the reasons steels is used extensively for earthquake-resilient constructions (Abed et al., 2021).

Additionally, the construction process is also made better by the incorporation of steel into the construction. The parts of the structure can be fabricated off-site and then assembled on site which leads to fast construction, elimination of wastage, and the quality of the steel is easily controlled. Thus, in huge projects where more time is a constraint prefabricated steel sections can be installed at the site and erections are done quickly reviving the phase of construction over concrete casting in situ. There is an obvious correlation between the efficiency and the cost reduction that comes with the use of steel compared to other materials even if the price per unit might be higher than other kinds of materials project is its superior strength-to-weight ratio, which allows engineers to design structures that are both strong and lightweight. Steels ability to handle tensile forces makes it ideal for beams, which must resist bending moments, and columns, which need to withstand compressive forces. In comparison, concrete, though strong in compression, is weak in tension and usually requires reinforcement (typically in the form of steel rebar) to handle tensile stresses. By using steel alone, we can simplify the design process while achieving better overall performance.

Another significant advantage of steel is its durability. Steel is highly resistant to a wide range of environmental factors, including fire, corrosion, and extreme weather conditions. Modern protective coatings can enhance steels resistance to corrosion in outdoor or humid environments, which is particularly beneficial for long-term durability in high-rise buildings exposed to the elements. Furthermore, steels ductility allows it to deform under stress rather than breaking suddenly, which adds an important safety margin in cases of extreme loading, such as earthquakes or high winds. This ductility is one of the reasons steel is so widely used in earthquake-resistant design (Abed et al., 2021).

Moreover, the use of steel enhances the construction process itself. Steel components can be prefabricated off-site, which reduces construction time, minimizes material waste, and improves quality control. In large projects, where time is a critical factor, prefabricated steel components can be delivered to the site and assembled rapidly, allowing the building process to proceed faster than traditional on-site concrete casting. This efficiency translates directly into cost savings, making steel a cost-effective option over the long term, despite its typically higher material costs upfront.

2.Project Context

In this specific project, transitioning from concrete to steel brings multiple performance improvements to the six-story commercial building. The column and beam designs must meet the buildings functional requirements while optimizing load distribution, material efficiency, and structural safety. The original concrete design posed challenges in terms of weight and bulk, particularly for the structural elements on the lower floors, which must support the cumulative loads of the floors above. Concrete, though strong in compression, would result in heavier, bulkier columns and beams, thus requiring stronger foundations and potentially increasing the overall cost of construction.

By switching to steel, we aim to reduce the overall weight of the structure, thereby decreasing the load on the foundation and enhancing the buildings load-bearing efficiency. Steel also offers greater flexibility in terms of design modifications. The slenderness of steel columns allows for more usable floor space, while the reduced weight of steel beams allows for longer spans, which can minimize the need for interior support columns. This can create open-plan layouts that are highly desirable in commercial spaces, offering greater versatility for tenants.

This project focuses specifically on the design of a continuous beam located on the fourth floor and a ground-floor column that supports this beam. These components were initially designed using concrete, but in the redesigned steel structure, the emphasis shifts to optimizing these elements for strength, weight reduction, and material efficiency. The design of the beam must consider bending moments, shear forces, and deflection, ensuring that the beam can support the required loads without experiencing excessive bending or deflection that would compromise the buildings functionality or safety.

Project Objectives

The main goal of this project is to calculate dissection and determine the most suitable steel column and steel beam for a six-story commercial building (Alvarez, 2023). These structural elements must conform to the Australian Standards (AS 4100-1998) for both safety and serviceability of steel structures. The specific objectives include:

1.Steel Column Design: Design a column that can bear the axial loads coming from the upper floors without buckling. This will include the slenderness ratio, the effective length of the member, and the type and mechanical characteristics of the constituting material (Gardner, 2019). The most suitable cross-section profile will be chosen depending on the desired overall performance as well as the economy in the usage of materials.

2.Steel Beam Design: Choose the cross-section of a continuous beam that can support both the vertical loads and the moments and shearing forces due to the floor loads (Electors et al., 2021). The goal is to verify that they can accommodate the load distribution while restricting deflection to a specific amount and keeping the moment and shear strength of the beam high enough.

3.Design Comparison and Optimization: Discuss different design solutions for the column and the beam side by side to consider each option from the load point of view, technological viewpoint, cost, and stability (Y?ld?z et al., 2021). It is important to choose the design that will provide the biggest production efficiency with minimal cost; however, safety and design standards must not be compromised.

Project Overview

Structural Elements Redesign of a Six-Story Commercial Building

The transformation project involves the modification of column and beam structures of a six-story commercial building based on the superior strength and efficiency of steel structures as opposed to concrete (Tenrio et al., 2024). This transition is for improving structural performance and managing material usage.

Column Design

As the column is located at the ground level, it must bear a considerable number of axial loads coming from the upper floors (Meena & Ramana, 2022). Being a member designed to take axial compression, special attention must be paid to bucking and slenderness. The Rectangular Hollow Section (RHS) was chosen for having less weight and more strength that can take both axial forces as well as lateral forces efficiently (Liu et al., 2023). High-strength steel options will be sought in the design of a material that will have reduced volume and possibly lower cost.

Beam Design

The beam is situated on the fourth floor and is a continuous member made to support floor loads. It is intended to be designed for withstanding bending moments and shear forces consideration of span length and loading will be important (Montuori et al., 2019). The I-Section Beam is selected based on the optimised performance of bending weight and the shear load while bearing minimal weight and material cost. To fine-tune the design of the frame, more options in beam layout are possible, such as synergistic steel-concrete beams. Increasing the performance and productivity of the organisation (Kanthasamy et al., 2022). It will follow the guidelines of the AS 4100-1998 in conducting checks for section capacity, member capacity, and connection details. A comparative analysis of various cross-sectional shapes under consideration will be made to identify the most appropriate design about its efficacy, economic viability, and practicality.

Scope of Work

The following is the design of a steel column and beam in a six-story commercial building. It is important to point out that the structural elements are to be safe, serviceable, and performant for the required use.

3.Column Design

Knowledge of the behavior of the ground-level column is important for the overall structural stability of the six-storey building, especially concerning the axial loads from the higher floors. In a multi-story building, the columns bear extreme axial compressive forces and thus the choice of the right cross-sectional shape and material is critical. Regarding these axial loads, the responsibility of the column in supporting such loads without buckling or warping under pressure is crucial for the stability of the building in context (Meena & Ramana, 2022).

The first consideration that arises when designing the column bears on either the bucking or slenderness factors since they reduce the load-barring capacity of the column. There are two ways in which Buckling can occur: Failure is a kind of buckling wherein the structures fail when the load is so great that it causes bending or sideways deformation of the compacted bar or column under compression. The probability for a column to buckle rises with its slenderness ratio which is defined as the ratio of the effective length of the column to the radius of gyration. Namely, a higher value of slenderness ratio reduces the bearing capacity of the member under compressive force and therefore should be minimized through structural designing.

Considering the need to meet the specific requirements of the project, the Rectangular Hollow Section (RHS) was found to be the most suitable cross-section for the column. The RHS also offers the best mechanical properties with the right combination of strength-to-weight ratio and the least usage of materials. It makes the overall weight of the column lighter than its traditional counterparts while maintaining the load-bearing capacity under axial compression and lateral force. The features of high strength and light weight make the RHS section popular in the current steel construction, especially in the application of columns for multistorey buildings (Liu et al., 2023).

The effectiveness of the RHS in carrying axial as well as lateral loads can be regarded as one of the attributes of the structure. Because of the sections rectangular shape, it can bear bending and torsional loads much better than more complicated shapes such as circular hollow sections (CHS) or I sections. Also, the closed profile of the RHS increases its torsional stiffness, which in effect makes the RHS more resistant to the twisting moments. This characteristic is particularly useful in tall building systems since the columns encounter both vertical loads and horizontal forces such as those caused by winds or earthquakes.

The employment of high-strength steel in the column also adds higher efficiency to the structure. Another benefit of high-strength steel is that thinner sections can be used to permit the necessary loads whilst still maintaining high levels of strength. When using a denser material for columns then the required amount of steel can be lesser along with decreased cost of the structure. Another advantage of the foundation design is the reduced weight which enables a lighter foundation to support less load and can be economical in the construction process.

Furthermore, the use of high-strength steel increases the stiffener capacity to bear axial loads without buckling the column. This property is of essence to make sure the column does not buckle under the high compression loads coming from the upper floors. With the use of high-strength steel, the design can achieve both structural performance and economic efficiency objectives.

Thus, the decision to use a Rectangular Hollow Section (RHS) at the ground level for the construction of the column is quite suitable in terms of strength-to-weight ratio and cost-effectiveness. The fact that RHS is capable of bearing both axial and bending loads, coupled with the use of high-strength steel to fabricate the column makes the idea structurally viable enough to meet the requirement of the buildings structure while using less amount of steel and thus offering least cost.

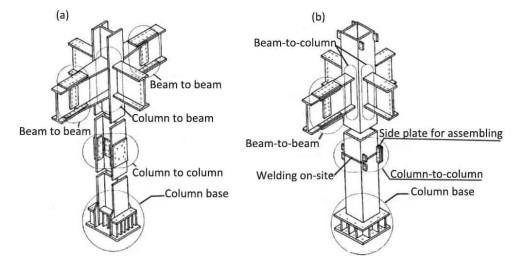

Figure 1 steel column design structure

[Source: (Havit Steel, 2020)]

4.Beam Design

Concerning the beam design of precast T-beams, there is an emphasis on the mechanical forces, namely bending moments and shear forces. The continuous beam, which is also found on the fourth floor, spans across some of the columns and also takes a lot of load on the floor (Rueda-Garca et al., 2022). Hence, it must be designed in such a way that it can handle both the strength of bending and shear. The I-Section Beam was first selected because it has been shown to defy bending moments as well as sheer forces with a minimal number of materials (Armaghani et al., 2019). The design will contain a working out that will show the ability of the beam to undergo the expected loads. Other beams that will be considered are the composite steel-concrete beams. These performance characteristics may include load-bearing capacity and material cost, where composite beams may show improved characteristics compared to conventional beams (Tsavdaridis et al., 2019). A comparison of these solutions will enable the determination of the optimum solution in beam design.

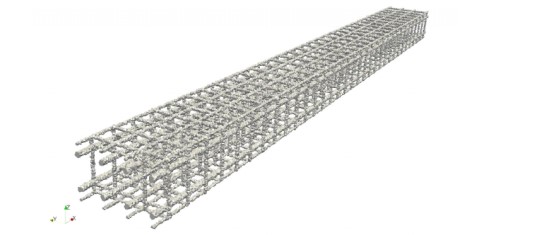

Figure 2 Steel beam design structure

[Source: (Radchenko et al., 2015)]

5.Design Comparisons

One of the critical steps involved in the design process is to consider several cross-sectional designs for the column and for the beam as well (Tsavdaridis et al., 2019). Each design will be assessed based on several factors: the structural capacity of the item, its ability to resist torsion, its suitability for manufacture and its cost. This comparison makes sure that the selected designs not only have the capacity to meet the structural demands but also possess a superior value for construction and the cost of the materials to be used (Foraboschi, 2020). The evaluation will comprise a comparison of how each design will function in various loading conditions and how it will be manufactured.

6.Serviceability and Safety

The final designs are also supposed to fit into serviceability and safety requirements. For serviceability, the designs will meet the deflection limit without a negative impact on non-structural elements like ceilings and partitions it will meet (Ma et al., 2023). Safety consideration will comprise the maximum requirement for load bearing and stability compliance to rule out the possibility of structures collapsing. It is also important to ensure that the column and beam designs meet the safety and serviceability requirements for the building structure.

7. Design of the Steel Column

7.1 Material Properties

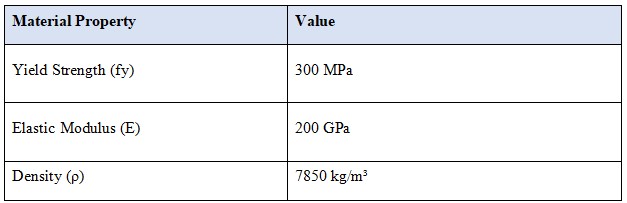

Steel, on the other hand, has several beneficial characteristics when applied to column design, such as high strength and flexibility (Tenrio et al., 2024). Material properties assumed for this design are:

Table 1 Material Properties of Structural Steel

7.2 Column Design Equations

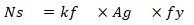

The process of designing a steel column involves coming up with a picture that would depict the load-carrying capacity of the column and whether the column is prone to buckling. The nominal section capacity Ns for a column is calculated using the equation:

Where:

- Ag = Gross area of the section,

- Fy = Yield strength of steel,

- Kf = Form factor, accounting for local buckling and slenderness.

In this equation, the form factor Kf adjusts for the effects of slenderness and local buckling, ensuring that the column has sufficient capacity to resist axial loads.

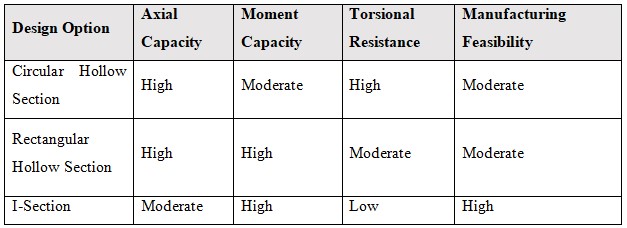

7.3 Design Options for the Column

Three design options were considered for the steel column, each with its own advantages and disadvantages.

- Circular Hollow Section (CHS): CHS columns perform very well in terms of torsional strength, and they are very efficient in terms of axial loads, as shown in Table 1. However, they provide lesser moment resistance than any other cross-sectional shape.

- Rectangular Hollow Section (RHS): RHS sections are also superior in moment capacity and are used majorly for structural purposes. They are also superior structures when it comes to the ability of the hook to resist axial and bending loads.

- I-Section: It also reveals that I-sections have outstanding abilities to resist bending moments; however, they are more susceptible to local buckling, particularly in axial compression force. However, they are easy to manufacture and also easier to fix on the structures that they are required on.

Table 2 Comparison of Column Design Options

After analysing the design options, the Rectangular Hollow Section (RHS) was selected for its high axial and moment capacity, balanced with its torsional resistance and ease of fabrication.

7.4 Effective Length and Slenderness Ratio

The slenderness ratio is critical in column design because it influences the risk of buckling. The effective length factor Kl depends on the column's end conditions. For a column with pinned ends, the effective length is the full height of the column. The slenderness ratio ?e is calculated as:

Where:

- le = Effective length,

- rg = Radius of gyration of the cross-section.

For the chosen RHS section, the effective length and radius of gyration are optimised to minimize the slenderness ratio, ensuring that buckling will not occur under the expected load conditions.

Design of the Steel Beam

5.1 Load and Moment Calculations

The design of the steel beam must account for both bending moments and shear forces resulting from the applied loads. For a uniformly distributed load, the bending moment at the mid-span of a simply supported beam is given by:

Where:

- w = Uniformly distributed load (20 kN/m),

- L = Span length (6 meters).

Substituting these values:

This calculation is essential to determine the beam's moment capacity and ensure that the selected section can resist the bending moment without yielding.

5.2 Beam Design Options

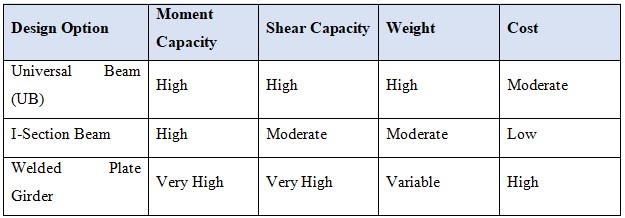

Three different beam sections were considered for the design:

- Universal Beam (UB): UBs are commonly used for their high moment resistance, but they are relatively heavy.

- I-Section Beam: I-sections offer a more optimised design in terms of weight and cost, with slightly reduced moment capacity compared to UBs.

- Welded Plate Girder: Welded plate girders are customisable and suitable for longer spans, but they are more expensive and labor-intensive to manufacture.

Table 3 Comparison of Beam Design Options

The I-Section Beam was chosen for its optimal balance between moment capacity, moderate weight, and cost efficiency.

5.3 Shear Force and Shear Capacity

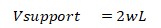

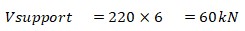

The shear force at the supports of the beam can be calculated as:

For a uniformly distributed loadw=20kN/m and span length L=6?mL = 6 , text{m}L=6m:

The I-Section Beam is capable of resisting this shear force without exceeding its shear capacity, making it suitable for the design.

Critical Reflection on Design Outcomes

Reflection on Column Design

The cross-sectional design of the RHS column, as well as the decision to use this particular section, was found to be advantageous in terms of axial strength as well as the ability to resist bending moments (Ma et al., 2023). The configuration of RHS provides a good strength-to-weight ratio, which is desirable from the structural point of view. This is because failure to meet the above-defined slenderness ratio adds to the eagerness to buck when loads are applied to the structure (Zhi et al., 2022). This is important because excessive thinning of beams may result in buckling and, hence, failure.

Even though the RHS has been able to meet the design criteria satisfactorily, as analysed earlier, there is scope for improvement (Franklin, 2019). An area which can be improved is the compatibility of high-strength steel. High-strength steel is a material that enables a decrease in the volume of used material with the possibility of increasing the level of safety. Thus, this reduction in material means that in addition to resulting in lighter structures, costs are trimmed, both in terms of the material itself and the work of constructing it (Tsavdaridis et al., 2019). Subsequent projects may also use high-strength steel to optimise the structure, thus reducing construction costs.

Reflection on Beam Design

The I-Section Beam was found to have complied well with the loads that were placed on it. It offered enough moment and shear resistance while being light in weight and cost-efficient (Rueda-Garca et al., 2022). It is widely recognised as a preferred section for beams that are easily shaped and is effective in carrying bending moments and shear forces in the most efficient manner proportional to the amount of steel used (Armaghani et al., 2019). In this regard, the choice enabled sufficient compliance to the structural performance characteristics of the building. However, these beams can be redesigned and improved considering the utilisation of distinctive materials. Steel concrete composite beams, for instance, are characterised by immense load-bearing capacity and efficiency ratios (Tenrio et al., 2024). These composite systems are a combination of both steel and concrete structures, which may result in higher performance and cost advantages. It is worth dealing with such alternatives to gain more insights and enhancements in future designs.

Safety and Serviceability Considerations

Safety and serviceability are two critical aspects that need to be met in steel structure design, and both of them have been covered in this project. There are normally design codes that are followed to the letter, for example, AS 4100-1998; these create limits to stresses, deflection, and stability (Ma et al., 2023). In the case of the column, the slenderness ratio and effective length were designed such that buckling could not occur; this constitutes a safety feature. By keeping these parameters to the required level, the design would be able to support different loads in terms of structure.

Conclusion

Therefore, the analysis of steel columns and beams of the six-storey commercial building has revealed how material density, the configuration of the cross-sectional area, and compliance with established code standards impact the performance, strength, and safety of the building structure. The replacement of steel for both the column and the beam from the initial concrete design has led to a more efficient, cost-effective, and versatile solution. This project could only be accomplished in steel, as this material has a higher strength-to-weight ratio and is very versatile with capabilities of loading it with compression and tension forces. The change of material has not only enhanced the load-bearing capacity of the structure but has also ensured a faster and better build.

RHS was the best for the column because it offered high axial and bending loads, torsional capacity, and in addition, was easy to fabricate. The RHS section is equally well suited to meet the high axial loads from the upper floors with adequate resistance to buckling and lateral torsion forces. This choice emphasizes the choice of staff who, in addition to being strong enough to withstand the forces characteristic of the structure, should not reduce the efficiency or cost of the material used.

In the beam design, the I-section is preferred due to a large moment of inertia which contributes to withstanding both bending moments and shear forces with minimal material consumption. Primarily, this type of structure has desirable characteristics for multi-story commercial construction because of the effective proportion of strength, affordable fabrication, and easy erection. This section also disperses the floor loads to the supporting columns and controls the deflection appropriately to sustain the long-term serviceability of the structure.

In compliance with the aforementioned AS 4100-1998, the design process has effectively complied with the standard safety and serviceability procedures for steel structures in Australia. The design procedure went through a section capacity check, member capacity check, and member buckling check for the components, and both the column and the beam arrived at the necessary performance. The above considerations were also integrated into the design process, including load distribution, deflection limits, and constructability of the final solution.

This project initiates the discussion on the selection of several designs and cross-sectional forms to obtain the most optimal combination between the characteristics of the structure and the costs of its fabrication. Though the designs of the column and the beam used here are the best suited for this particular structure, the numerous possibilities of alternatives revealed that there are innumerable potential methods to realize the same structural requirement, For example, the use of Circular Hollow Sections (CHS) for the column, or composite steel-concrete beams for the beam. The opportunity to evaluate these choices, considering the applied materials, cost of fabrication, and future serviceability is critical to most design strategies.

Consequently, as to the future development of steel design, the possible future direction should be highly inspiring. Recent developments in high-strength lightweight steel and green materials have the possibility of leading to a significant decrease in the weight as well as the ecological footprint of steel structures. High-strength steel especially permits the use of thin gauges that offer or improve on load-bearing capacity; implies lighter structures with less material costs and short construction durations. This is in harmony with the increasing tendencies that have developed in the construction industry towards the usage of more efficient and environment-friendly materials and methods of construction.

The extension of high computation software into the designs is another area of huge scope for future developments. Applications like FEA, design with parametric controls, and structural optimization are now available to enable the engineer to develop as well as model applications with high fidelity physical loads that mimic real conditions accurately. They allow for better predictions of how structures will perform under different loads making the construction safer and more efficient. Further, Building Information Modeling (BIM) is changing the way of steel design as it fosters enhanced cooperation of design teams, precise material requirement quantification, and seamless conversion of design data to formation data. BIM helps the creation of an entire buildings model and contains specific details about the steel components to enhance decision/choice-making at each phase of the project.

Lastly, this project has effectively demonstrated the significance of appreciating cross-sectional selection and specified material utilization, as well as revealed the diverse potential for future developments in steel design. Hinging on new materials, better construction methods, and improvement in computational technology, the steel design industry is in the process of growing. These innovations are contributing to the development of efficient superior and elastic constructions, which will form the cities of the future. The time will come when such technologies only enhance the design and analysis of steel structures for the construction of the next generation of buildings. A parametric design software, and structural optimization algorithms allow engineers to model complex loading conditions and optimize designs with unprecedented accuracy. These technologies enable more precise predictions of how structures will behave under various loads, leading to safer and more efficient designs. Additionally, Building Information Modelling (BIM) is transforming how we approach steel design by allowing for greater collaboration between design teams, more accurate material estimations, and smoother transitions from the design phase to the construction phase. BIM facilitates the 3D modelling of entire buildings, incorporating detailed information on the steel components, which improves decision-making throughout the project lifecycle.

In conclusion, this project has not only illustrated the importance of careful cross-sectional selection and material optimization but also highlighted the broader possibilities for future advancements in steel design. By leveraging new materials, innovative construction techniques, and advanced computational tools, the steel design industry is evolving rapidly. These innovations are driving the creation of lighter, stronger, and more sustainable structures that will shape the skylines of the future. As these technologies continue to improve, they will further refine the design and analysis of steel structures, making them even more effective for the next generation of buildings.

Are you struggling to keep up with the demands of your academic journey? Don't worry, we've got your back!

Exam Question Bank is your trusted partner in achieving academic excellence for all kind of technical and non-technical subjects. Our comprehensive range of academic services is designed to cater to students at every level. Whether you're a high school student, a college undergraduate, or pursuing advanced studies, we have the expertise and resources to support you.

To connect with expert and ask your query click here Exam Question Bank