Concrete Technology and Construction Methods CST2031

- Subject Code :

CST2031

Part 2

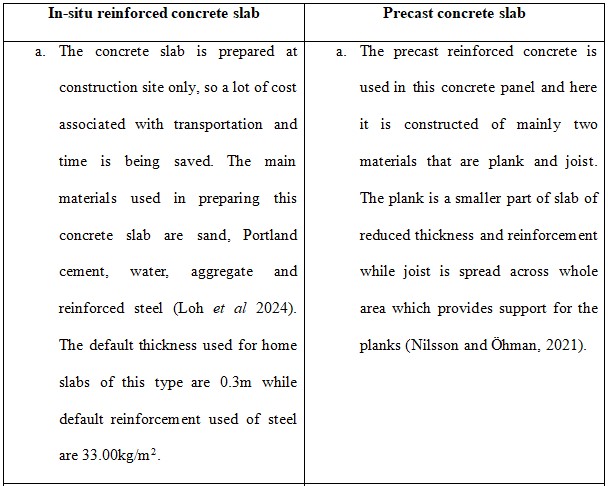

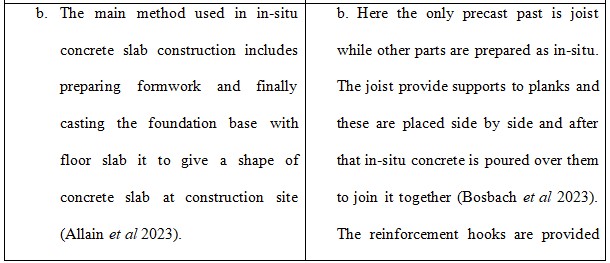

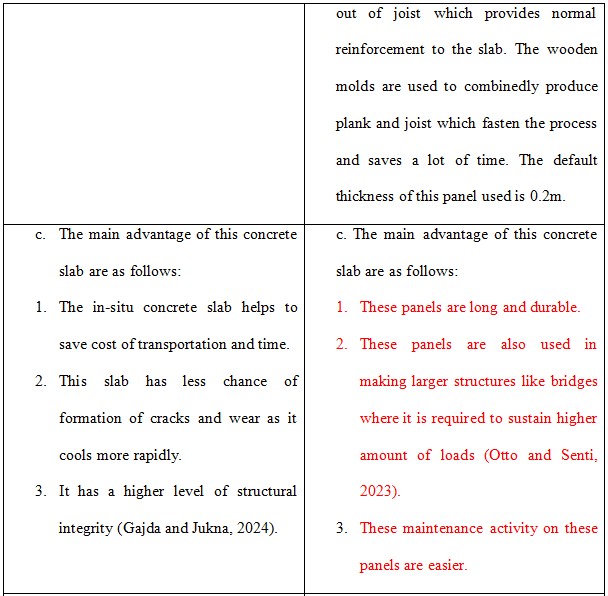

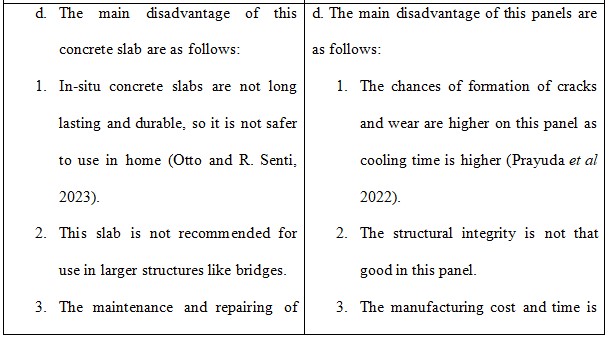

2.1 Comparison

The advantages comparison between in-situ precast concrete slab are provided in below table.

Table 1: Advantages comparison of concrete slab

(Source: Self-created in MS Word)

2.2 Formwork / shuttering

Formwork is a process of providing a required geometrical shape, design and strength to the concrete while shuttering is a process of providing support and making concrete part stable before conversion to concrete (Sefrin et al 2022). The shuttering is commonly made of steel or wood. The framework is also referred as initial structure or design provided to building.

Figure 3. Framework and shuttering

(Source: Krishna, 2018)

The suspended concrete floor is mainly used in construction of any structure.

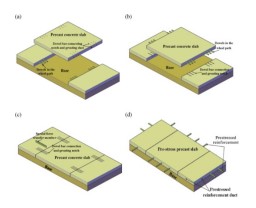

2.3 Precast

The precast concrete is developed in a reusable mold form in a controlled environment and then transported to construction site. The example of such precast concrete a0re floors, panels, piles and roofs.

Figure 4. Precast concrete beam slab

(Source: Fang, 2022)The precast concrete floor type is commonly used in construction work because of faster construction work and reduced labor costs.

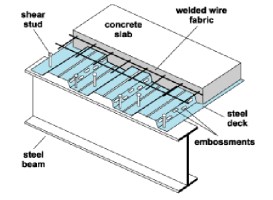

2.4 Composite

The composite concrete is mixture of different aggregates like stones, gravels, cement and sand with steel bars placed at bottom for providing support. The concrete structure formed from this process has higher compressive strength with addition of steel rods or bar, its tensile strength also enhances.

Figure 5. Composite floor with steel deck

(Source: Begum, 2013)

The composite concrete floor with steel or aluminum deck are commonly used in construction work as these materials provides both strength and lightweight features to concrete floor (Takahashi et al 2022). Steel is a higher strength material whose modulus of elasticity is 210GPa while aluminum has density of 2100 kg/m3. Then steel helps to keep strength of concrete floor higher while aluminum keeps material body lighter.

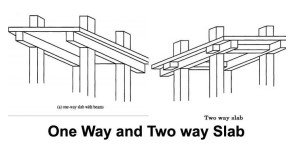

2.5 One- and two-way slab

The load is acting in only one direction in one way slab as it has less steel content while loads are acting in two directions in two-way slab as reinforcement is done in both directions. If the ratio between larger and shorter span of slab is less than 2 then it is termed as two-way slab otherwise it is one way slab (Zou et al 2022). The reinforced bars are placed parallel to shorter span side in one way slab.

Figure 6. One- and two-way slabs

(Source: Selim et al 2019)

One way slab is generally used for short spans, and it is also applicable for longer structures. The two say slab is generally suitable for longer span slab on floor and it is mostly applied on rectangular or square shaped structures.

Are you struggling to keep up with the demands of your academic journey? Don't worry, we've got your back!

Exam Question Bank is your trusted partner in achieving academic excellence for all kind of technical and non-technical subjects. Our comprehensive range of academic services is designed to cater to students at every level. Whether you're a high school student, a college undergraduate, or pursuing advanced studies, we have the expertise and resources to support you.

To connect with expert and ask your query click here Exam Question Bank