Optimization of Hydrogen Liquefaction Processes: A Case Study with Aspen HYSYS

- Subject Code :

CHPR3404

Introduction

The transport and storage of hydrogen in a liquid state is critical for developing a hydrogen export

industry in Australia. The liquefaction process and storage of liquid hydrogen must be efficient and

safe to make liquid hydrogen viable as an energy carrier on an economic and ecological basis.

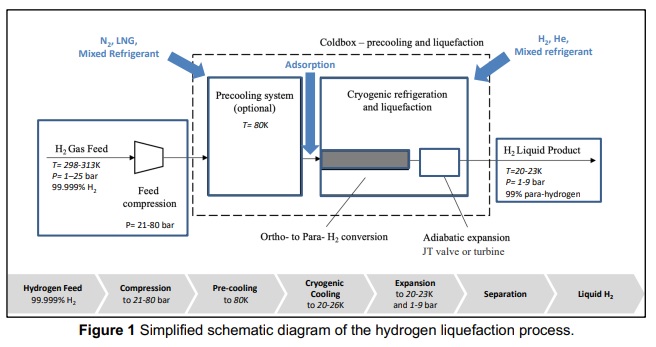

Figure I presents a simplified process block diagram of a typical hydrogen liquefaction process. The

hydrogen feed is typically received from the relevant hydrogen production plant [1] at between (298

and 313) K and (I to 25) bar The purity is dependent on the upstream production

processes (e.g., hydrogen produced by steam methane reforming and purified with pressure swing

adsorption has a purity of typically 99.999%, whereas hydrogen produced by electrolysis is reported

to produce purities over 99.9999%[31).

The first step of the liquefaction process is pre-compression of the hydrogen feed [4]. The hydrogen then undergoes an optional precooling stage to (80 to 110) K and an adsorption stage to remove impurities that may freeze out during cryogenic liquefaction [5]. The hydrogen is then cooled using a closed-loop cryogenic refrigeration cycle down to temperatures between (20 and 30) K. This cooling step involves (continuous or batch) catalytic conversion of ortho- to para-hydrogen [6]. The final step is adiabatic expansion, which either takes the form of Joule-Thompson expansion or turbine expansion. [7] Once the fluid is cooled to approximately (20 to 23) K, a cold separator is used to capture the condensed liquid. The liquid product is usually stored at (20 to 23) K and (1 to 9) bars with a specified para-hydrogen fraction greater than 98%. [6] The ortho- to para-hydrogen conversion, on average, consumes about 18% of the total energy consumption involved with hydrogen liquefaction and storage. [4, 7]

Similar to the LNG, hydrogen liquefaction processes can be broadly classified into three groups [8]:

- Cascade liquefaction process;

- Mixed refrigerant (MR) process; and

- Expander-based process.

Cascade processes are not considered in this assignment due to their relatively high specific energy consumption (SEC).

Mixed Refrigerant Processes

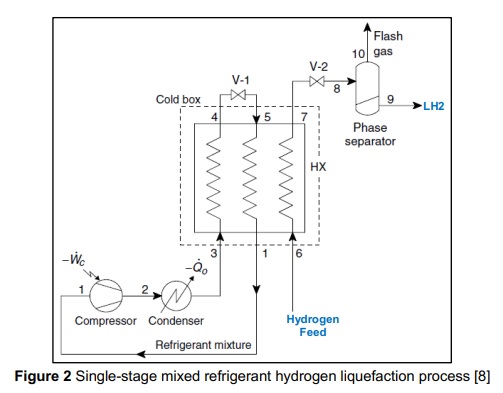

Figure 2 shows the simplest of the mixed refrigerant hydrogen liquefaction processes that do not have any phase separators. This process is also called the single refrigerant process and can be used in both the precooling and cryogenic cooling cycles, with varied refrigerant types and compositions.

Typically, the precooling process refrigerant mixture consists of methane, ethane, propane, butane, pentane, and nitrogen, whereas the cryogenic process refrigerant mixture consists of helium, hydrogen, neon, and nitrogen. The compression system includes several compressors with intercoolers and aftercoolers. The MR stream temperature can be changed after an isenthalpic expansion or throttling process, depending on the fluids Joule-Thomson coefficient (!"#):

- If !"# > 0, the temperature will decrease.

- If !"# = 0, the temperature will not change.

- If !"# < 0>

Therefore, in the process of adjusting MR composition, it is important to keep !"# positive to ensure there is a positive temperature approach across heat exchangers.

A more complex MR process with a phase separator between the heat exchangers is recommended in this assignment, to separate high boilers and low boilers. Refer to Section 6.7 fig. 6.24 of the book Cryogenic Mixed Refrigerant Processes [8].

- Expander-based processes

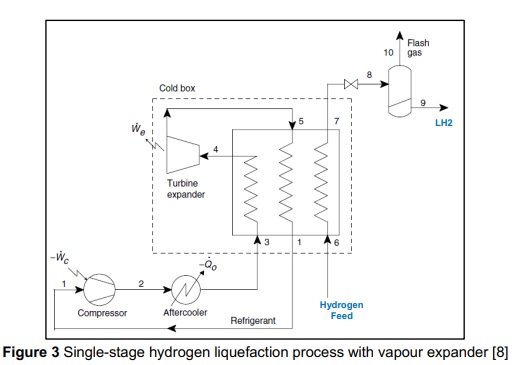

Turbine-based processes are also called vapour expander processes, and they are simple and can start up and shut down quickly. Single Expander Reverse Brayton cycle is the simplest of the turbine processes and is shown in Figure 3.

The refrigerant is compressed to a high-pressure and precooled in the heat exchanger and expanded to low temperatures in a turbine. The cold, low-pressure refrigerant is warmed up in the heat exchanger to cool the hydrogen feed and the high-pressure refrigerant. The refrigerant can consist of nitrogen, methane, helium, neon because of their low normal boiling point (below -163 C). As the expansion process is isotropic instead of isenthalpic, vapour refrigerant temperature will not increaseduring expansion, which is simpler than J-T valve expansion in terms of selecting refrigerant. As single-expander Reverse Brayton cycle has very low cooling efficiency, and therefore, an extra expander should be added into the system in this assignment (Brayton Cycle with two-stage expanders: not two expanders in series). Please refer to Section 6.7 fig. 6.60 of the book Cryogenic Mixed Refrigerant Processes [8], where HX-2 & HX-3 can be combined as one heat exchanger.

Design Objective

You will conduct two case studies as shown in Table 1 using Aspen HYSYS (steady-state mode) and optimise the total specific energy consumption (target SEC < 10>

- Refrigerant compositions. It should be noted that refrigerants can be single component, binary mixture, ternary mixture, or multi-component mixtures.

- Refrigerant flowrates.

- Compression/expansion unit specifications.

| Case | 1 | 2 |

| Pre-cooling Cycle | MR Process (C1-C5, N2) | MR Process (C1-C5, N2) |

| Cryogenic Cycle | Vapour Expander Process (He, Ne, H2) | Vapour Expander Process (He, Ne, H2) |

| Thermal Package | Peng-Robinson | REFPROP |

Inputs / Assumptions

- Hydrogen feed (100 tons per day) @ 298.15 K (25 C) and 30 bar.

- Liquid hydrogen product @ (20 to 21) K and 1.5 bar after the final phase separator (? 90 TPD).

- Intermediate temperature between precooling and cryogenic cooling = (110 to 80) K.

- Mixed refrigerants inlet condition @ 298.15 K and 50 bar.

- Compressor adiabatic efficiency to be 85% for hydrocarbon / nitrogen fluid and 80% for light

gaseous fluid (hydrogen, helium and neon). - The compressor ratio should be below 3.

- Expander isentropic efficiency is set to be 85%.

- Heat exchanger minimum temperature approach ? 1 K.

- The pressure drop across heat exchangers to be 0.1 bar. No pressure drop across air-fin coolers.

- Ambient temperature = 298.15 K.

- ortho-to-para hydrogen conversion is not considered (use HYSYS default hydrogen).

Deliverables

- HYSYS models for two optimum hydrogen liquefaction systems.

- A report containing the HYSYS models development methodology, PFD, key parameters, results,

limitations, and recommendations. - Discussions of larger-scale capacity (500 tpd) scenarios in terms of equipment limitations and

CAPEX.

4. Brief explanation of ortho- and para-hydrogen isomers, conversion methods, and why this

conversion is important to Hydrogen Liquefaction industry (Max 1 page).

5. Discuss the thermodynamic model selection and the impact on the overall process (Exergy

efficiency and SEC).

Are you struggling to keep up with the demands of your academic journey? Don't worry, we've got your back! Exam Question Bank is your trusted partner in achieving academic excellence for all kind of technical and non-technical subjects. Our comprehensive range of academic services is designed to cater to students at every level. Whether you're a high school student, a college undergraduate, or pursuing advanced studies, we have the expertise and resources to support you.

To connect with expert and ask your query click here Exam Question Bank