Remanufacturable Li-ion Battery System: Sustainable EV Solution

- Subject Code :

ME2502

- Introduction

Design, manufacturing and testing of Remanufacture-able Li-ion batteries (RB) system. Liion batteries (LiB) used in electrical vehicles typically have 10-20 years of life, they normally cannot be used when their performance decrease to 80% of original designed capacity for Electric Vehicles (EV). The UK is one of the biggest electric vehicle markets in the UK with 339,000 tonnes of automobile batteries to reach their end of life by 2040. Thus, demonstrating the vast potential of remanufacturing lithium-ion batteries in the UK. With the increase of EV uptake, there will be more and more (estimated at millions of tons) LiB waste, which is going to be a big problem to solve in the imminent future. At least 50% of these batteries must be reused as per EU legislation.

Remanufacturing, as one End of Life (EoL) strategy in the Circular Economy and can be potentially used to tackle this problem. Remanufactured products can save up to 80% in production and energy costs whilst generating lower CO2 emissions. Up to 85% of a remanufactured products weight can come from used parts thus reducing environmental and recycling impacts. Remanufacturing batteries saves lithium and cobalt being further mined and helps save the environment (https://www.youtube.com/watch?v=kSS_5vidrXE). The key remanufacturing success factors are quality, lead-time and cost. Currently the remanufacturing of LiB is not well practiced due to the inefficiency and high cost associatedwith remanufacturing process. The system needs a lot of manual work including hammering and heating. This process is costly and harms the environment.

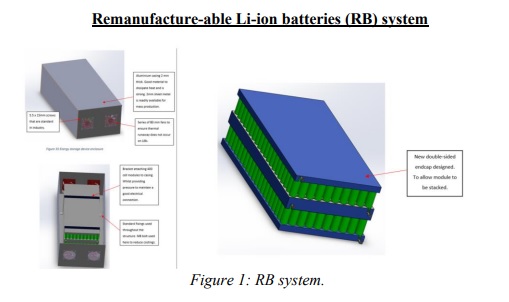

The current remanufacturing process needs to be redesigned to increase the efficiency and reduce the cost. Cost of material, cost of manufacturing, disassembly time and assembly time of the LiB are some of the influential parameters driving the costs of the remanufacturing process higher. This project aims to solve this problem through providing a LiB cover design through CDIO technique and design a cover and metal-strip that is of low cost (lightweight) and easily remanufacturable (takes less time and has lower number of components to assemble and disassemble). The design is intended to be used for domestic purposes. Project targets several Sustainable Development Goals and Net Zero strategy 2050. Figure 1 shows complete 100cells remanufacturable battery system design including battery management system, fans, external cover etc. to get you started.

- Task

Week 7: Finalize CAD & Cost Week

8: Extract Bill of Material & Drawings Week

9: Finish Poster & Drawings Week

10: Submit Poster and Drawings To assist you in these tasks, an Advisor is assigned, with an allocated 30min weekly meeting on Tuesdays, which should be the main point of contact. You can also book a WASS meeting with your advisor.

As you are expected to work as professional engineers. The role of your Advisor is purely to guide you in the process and discuss design options with you, not tell you what you need to do. Furthermore, there will be a need for you to make executive decisions when it comes to any area that this brief has not covered. The information in this brief is all that the customer has provided you with, and therefore anything else is left at your discretion.

Deliverable 1: Technical Drawings

From your CAD model of complete 100 cell RB system including fans, circuits etc., A3

technical drawings in PDF format, fully compliant with the BS8888:2020 and associated

standards must be provided, covering:

- 3 selected detail drawings of individual manufactured components that

form cover of RB system. - 1 Fabrication drawing of the complete cover of the RB system.

- 1 General Assembly of the RB system incorporating all major components

- Bill of materials for the complete General Assembly, intended to show the cover fabrication sub-assembly

Deliverable 2: Single Page Manufacturing Poster (25%, Chao)

The RB system is made of 100 cells that need to be assembled together. Manufacturers are always trying to increase the efficiency and reduce the cost. Manufacturing efficiency and cost can be affected by selected manufacturing process.

- You are to provide following information in a PDF one-page A2 poster:

- Provide a detailed description of all the steps involved in manufacturing

and assembling the RB system. - Provide a justification for the jigs/fixtures used in the manufacturing of the

RB system cover, highlighting their features and functions and how they

contribute to ensuring the system's performance and efficiency. - Provide a description of the cost, time and efficiency analysis of the RB

system. - Provide application of quality control and lean manufacturing for your RB

system manufacturing. - Convey the results of your RB system manufacturing process in a concise

and appealing single page poster, with high quality visuals.

Note that, at this stage, you should assume a production volume of A. 5000 and B. 50,000

RB systems/year.

Important: All students are expected to be involved with all parts of the project and contribute

to all deliverables. Failure to do so will means learning outcomes have not been met, and a

pass grade will not be awarded.

Are you struggling to keep up with the demands of your academic journey? Don't worry, we've got your back! Exam Question Bank is your trusted partner in achieving academic excellence for all kind of technical and non-technical subjects. Our comprehensive range of academic services is designed to cater to students at every level. Whether you're a high school student, a college undergraduate, or pursuing advanced studies, we have the expertise and resources to support you.

To connect with expert and ask your query click here Exam Question Bank