Warehouse & Storage Technique Assessment

- Subject Code :

LSC801

- University :

Massey University Exam Question Bank is not sponsored or endorsed by this college or university.

- Country :

New Zealand

LSC801 Warehouse & Storage Technique

Assessment 1: Warehouse Scenario A Jim Olsen Storage

Weighting: 25%

This scenario is fictitious and therefore, there is no need to contact any companies.

Read the case study scenario below and then, role playing as a warehouse specialist, complete the assignment in the form of a report.

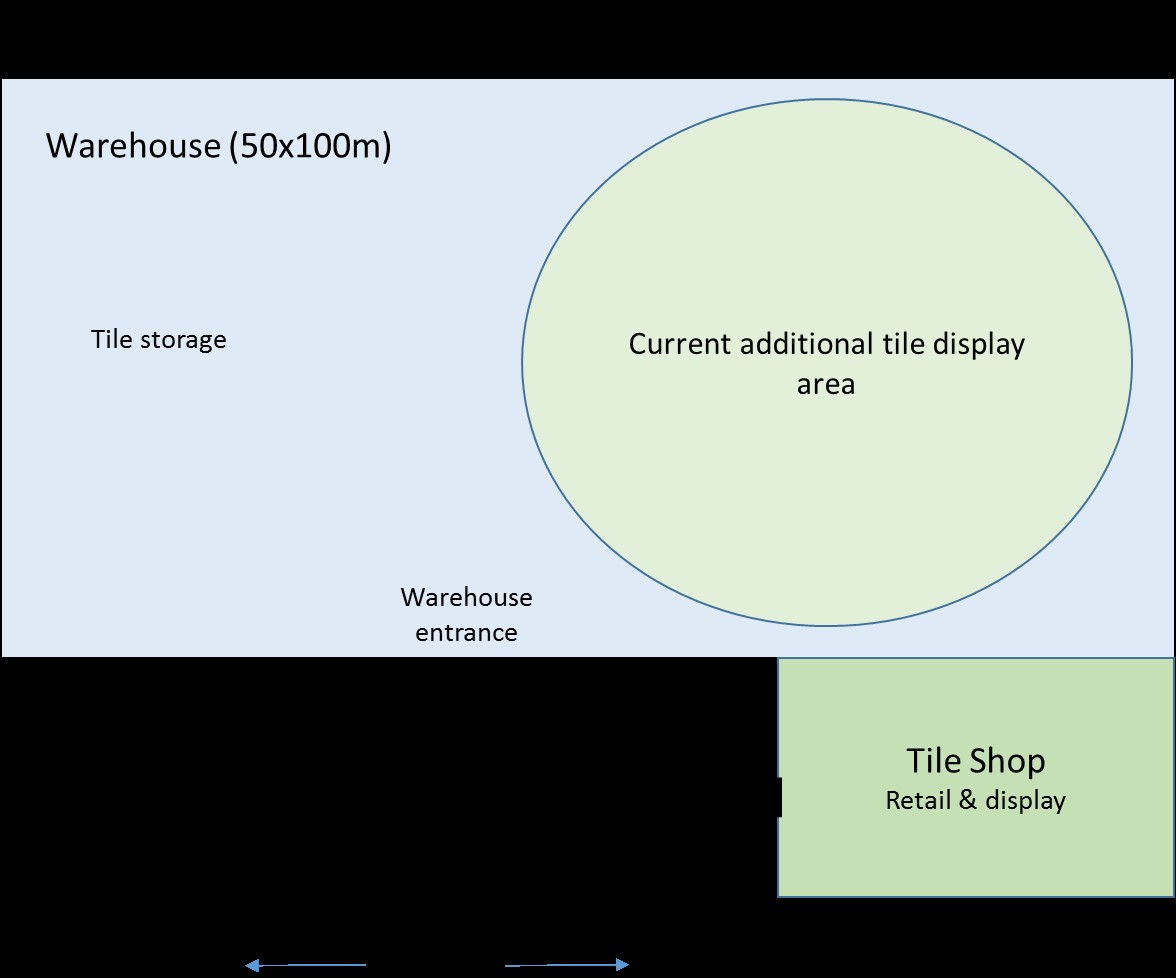

Jim Olsens Current Business

Jim Olsens current business is selling interior and paving tiles to individuals and businesses in a New Zealand city. He stores tiles and tiling accessories in a warehouse (50 x 100 m) adjoining his retail shop. Tile shipments arrive at the front of the warehouse, where they are unloaded by his worker and stored. A forklift is used for heavy work. Some tiles are unpacked and displayed either in the shop or in an area of the warehouse adjacent to the shop. The tiles come in several categories, being: size, durability, inside/outside, wall/paving, and quality (high quality tiles are manufactured in Italy, low cost tiles are manufactured in Southeast Asia).

Large sale orders are loaded via forklift onto customer vehicles at the entrance to the warehouse, but Jim also has a van if he needs to deliver small orders to building sites. Non- business customers usually load their own vehicles but again, Jim can deliver them if requested to do so.

Storage of tiles and associated accessories take only about half the warehouse. The other half, which is excess capacity, is currently taken up by additional display and consequently customers are permitted into the warehouse, sometimes unsupervised.

Currently Jim uses a spreadsheet to keep track of his stock (MS Excel). Shipments are labelled manually when stored in the warehouse with an inventory number taken from the spreadsheet.

Jims tile business is unlikely to expand and so he expects the excess storage capacity to remain into the foreseeable future. He might reduce costs by moving to a smaller facility but moving is not a practical proposition for the purposes of this scenario.

Refer to the following diagram for a schematic of Jims warehouse and shop. Furthermore, some images of Jims warehouse are available at the end of this document.

New Business Opportunity

Two nearby businesses are aware of Jims underutilisation of storage space and have asked if they can lease space for storage of their own stock. Jim is keen to do this in fact he sees this as an opportunity to become the owner/manager of a local collaborative warehouse.

The interested parties include:

- A large dairy/grocery store that wants to store bulk food (e.g. rice, flour, canned goods, drinks, ) and other non-perishable goods typically found in a grocery store (cleaning products, for example); and

- An automotive spray painting shop that wants to store oil-based paints, thinners, and associated equipment (e.g. spray guns, overalls, hoses, gloves, masks and safety shoes, etc.).

Jims concept is that he will be responsible for storage, layout and management of all stock being stored in the warehouse and he has confirmed that these businesses are happy to provide him with their order data and any other information he might need.

Jim has calculated that there is enough space in the warehouse to satisfy the storage needs of all three businesses, overall space utilisation is estimated to be 40% for Jims Tiles, 40% groceries, and 20% paint shop goods. To achieve this, Jim will restrict tile display to his retail shop and the warehouse will be dedicated to storage only. Jim will also need to become more efficient at storage.

In terms of item profiling, Jim has informed you that his fastest moving item is a low-cost white bathroom tile made in Indonesia, named Z-Tile. It most often sells in relatively small batches and comes in 10 kg packs that can be lifted by a fit person. Sales of this tile are usually accompanied by an interior grout called X-Grout, which comes in 5 kg plastic tubs. Together these two products are the top sellers in terms of the number of times each item is sold and by overall quantity, and consequently they take up approximately 15% of Jims tile storage area. At this stage there is no similar information available from the grocery store or the automotive paint shop.

Finally, while you have no data for the grocery store and paint shop finances, you will assume for the purposes of this exercise that all three businesses have similar problems with ship errors, shrinkage, data entry, and lost product and all other factors are equal. You have some financial data for Jims Tiles and, based on industry standards, a WMS is estimated to bring the following annual savings to Jim: pick productivity savings at $10,000; increased accuracy savings at $5,000, and reduced shrinkage & loss savings also at $5,000. An investment in a WMS acquired as Software as a Service (SaaS) will cost $16,000 per year.

Your Assignment

It is clear to Jim that his current processes and technology are woefully inadequate for a collaborative warehouse. Consequently, Jim wants to explore the key technologies, operations, procedures and processes that he will need in order to turn this opportunity into reality, and he has contracted you to prepare a report recommending ways to do this.

You are to write a 1500-word report (not including appendices, citations and references) that describes the following:

- Key technologies currently available (e.g. warehouse management systems);

- Best practice operations, procedures, and processes used in the storage of different products and commodities; and

- How these might be used to best advantage in Jims

Having described the state of the art above, you need to:

- Make fully justified recommendations on the likely best fit for Jim Olsen Storage in the future. Base your recommendations on the assumption that Jim Olsen Storage (JOS) is a small to medium size storage operation with a limited budget.

- Write a conclusion at the

Note: You must make reference to models, frameworks, concepts, and terminology that you have encountered in class and in your textbook.

This scenario has been developed to cover the bulk of Learning Outcome (LO) 1 for LSCM801 and provides most of the information you need to complete this assignment. However, any assumptions you make need to be stated as such, and you need to explain why you consider them to be realistic assumptions.

The aim is to apply the theory to the given situation (demonstrate knowledge) and identify improvements (evaluation and critical thinking). It is not enough to merely repeat theory you need to describe and explain a companys processes and circumstances in terms of the theory. The challenge for you is to keep your report succinct and to the point!

APA referencing guidelines are to be followed and evidence of wide reading is expected for a paper at this level, i.e. a minimum of four authoritative sources to be acceptable, including the textbook. For more information on the assessment requirements, please refer to the table on the next page and to the Assessment 1 marking rubric on Moodle.

Learning Outcomes Covered by Assignment 1: Warehouse Scenario Report A

This assessment covers Learning Outcome 1. Refer to the table below.

LO1. Systematically review key technologies (e.g. warehouse management systems), operations, procedures, and processes used in the storage of a variety of different products and commodities and how these may be used to best advantage in the warehouse. |

|

Warehouse operations 25% of your effort |

Given the range of goods to be stored in the warehouse, and their ownership, consider and recommend the optimum layout and storage equipment to be used. Analysis should include whether goods should be stored separated by ownership and/or other category such as compatibility (chemicals alongside/above foodstuffs, for example). |

Warehouse procedures and processes 25% of your effort |

Describe cross-docking and recommend an appropriate process for JOS, with a diagram. What information would be required for cross-docking to be viable in this scenario? (10%) Given the sales and storage information on the Z-Tile and X-Grout, consider and recommend optimal placement of these goods in the warehouse for efficiency, taking into account their popularity, characteristics, and safety aspects. (15%) |

Warehouse technologies 50% of your effort |

Order picking: briefly describe range of order picking technologies, then justify and recommend a best fit for the operation under consideration. (20%) Warehouse Management System (WMS): Calculate the return on investment (ROI) and payback period that a WMS would typically be expected to bring to the business under consideration; Briefly describe range of WMSs; and Recommend and justify two WMSs you consider would be appropriate for the operation under consideration and identify the providers of these systems. (30%) |