Competency Demonstration Report

- Country :

Australia

INTRODUCTION

CE 2.1

Period: 12 July 2012 to 31 August 2022

Designation: Senior Engineer (Machinery)

CE 2.2

Keppel Shipyardhas an unrivaled track record for repairing, converting, and upgrading a diverse range of vessels.Our marine expertise includes

- Conversion of Floating Production, Storage, and Offloading (FPSO) / Floating Storage and Offloading (FSO) vessels, Floating Storage and Re-Gasification Units (FSRU), and drillships

- Repair all types of marine vessels, including tankers, containerships, bulkers, and LNG / LPG carriers.

- Upgrading and life extension of vessels

- Jumboisation of vessels

- Fabrication of turrets and topside modules

CE 2.3

BACKGROUND

Since the magnaflux inspection of the propulsion shaft involves three steps, namely 1) removal of the propeller, 2) Disconnecting the coupling bolts and intermediate shaft 3) removal of the propulsion shaft, now I have to design the procedure for the disconnection of the above items in a sequential manner. The steps involved are

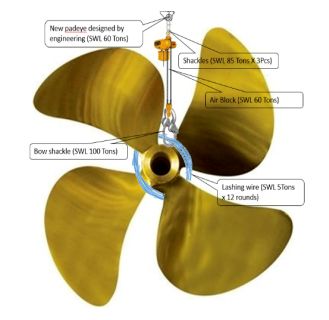

- Inspection of the aft stern construction drawing determines the strong point for lifting a propeller blade, after which design the pad eyes.

- Arrangement of the lifting gears, lashing equipment, air pumps, hydraulic fittings, hoses

- Prepare a lifting plan for the entire process.

- Prepare and conduct a JHA (Job hazard analysis ) as the tonnage of the equipments more than 20T and its complexity.

- Preparation of the lifting gear certificates and organizing the QA team for inspections.

- Coordinate the inspection between the owners and classification societies.

- In a statement of the above items sequentially and inspect at various stages.

CE 2.4

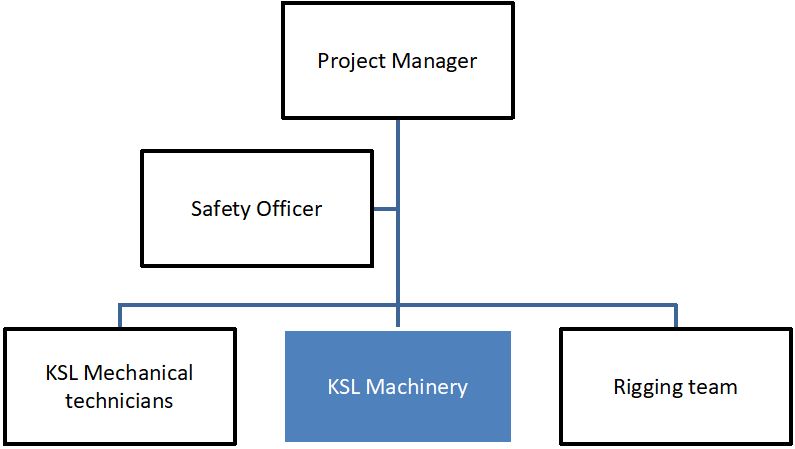

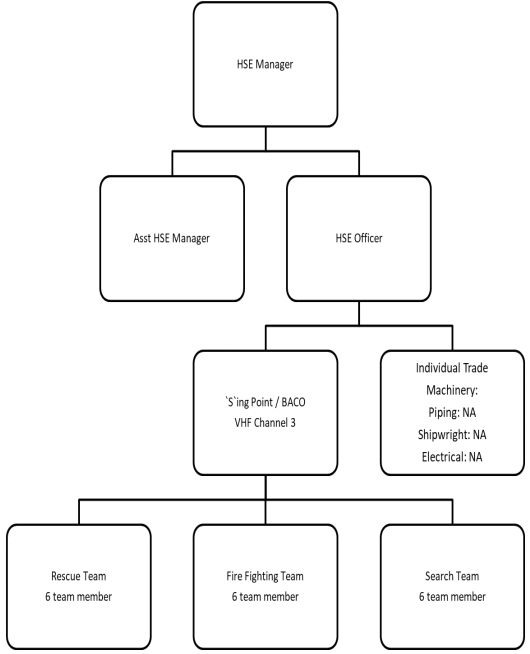

The organizational flow chart is attached and my position is highlighted in blue

PERSONAL ENGINEERING ACTIVITY

CE 2.5

From the beginning of the process, I had first to fetch all the tonnage and dimensions of the items involved. For that, during the kickoff meeting, I highlighted the relevant drawings that have to be provided, which the owner circulated through the ship repair manager.

Once I receive the data, I circulated the above drawings to the engineering department to calculate and verify the pad eyes. Once the pad eyes are confirmed, I sat with the rigging team to generate a detailed lifting plan for the propeller, intermediate shaft, and tail shaft separately based on the tonnages. Further, the above plan was sent to the engineering department for further stress calculations. The above department advised further for the change in the lifting gears as required.

CE 2.6

This work method statement defines the lifting and shafting of the Tail Shaft and Intermediate Shaft.

Propeller 42ton / Tail Shaft 10.2M X 1.45 M, weight 26T / Intermediate Shaft 10.4M X 1.45M, Weight 21T

Preparation before operation

Document/Site Preparation:

- Preparation of relevant documents for lifting arrangement. (Responsible Party: Machinery Lead)

- Lifting gear certificates - (Responsible Party: Lifting Lead)

- Prepare lifting plan:

- Choosing the appropriate lifting gears (chain blocks, shackles, and wire slings).

- Conduct JHA before the lifting/shifting operation with all personnel reflected in Organization Chart Submit relevant documents (lifting arrangement, calculation, MPI reports, and risk assessment) for review. (Responsible Person: KSL machinery Lead)

- Site preparation

- Any obstruction items are to be cleared before the lifting/shifting operation.

- Communication check between KSL Lifting Lead and KSL Production Team using a walkie-talkie.

- Ensure all material in the tail shaft and intermediate shaft are removed.

- All removed handrails and walkway platforms are suitably secure, and alternative walkways should be provided

- The lifting area should be barricaded, and only authorized personnel should enter.

- All additional lifting gears must be checked and verified by the safety Lead before the lifting/shifting operation.

- Coordinate and highlight in the Castillo de Catoira VSCC meeting the withdrawal of the propeller, Tail shaft, and Intermediate Shaft to be carried out. PTW to apply for Dismantling and Boxing up activities.

- A Lock out, Tag out should be installed on the Turning gear to avoid any accidental turning of the engine while working on the propeller at the dock bottom.

CE 2.7

Lifting and shifting of propeller

- Once the lifting arrangement is done, set up the hydraulic tools and loosen the propeller nut. Unscrew the nut and lower down the nut to the floor with the help of the cradle.

- Put the necessary marking on the propeller and prepare hydraulic tools for propeller jumping.

- Hook up the forward chain blocks to the propeller and slowly jump the propeller from the tail shaft taper.

- Once the propeller is free from the tail shaft, set up chain blocks on the rudder side, pull the propeller from the taper, and make it straightforward for about 1 foot.

CE 2.8

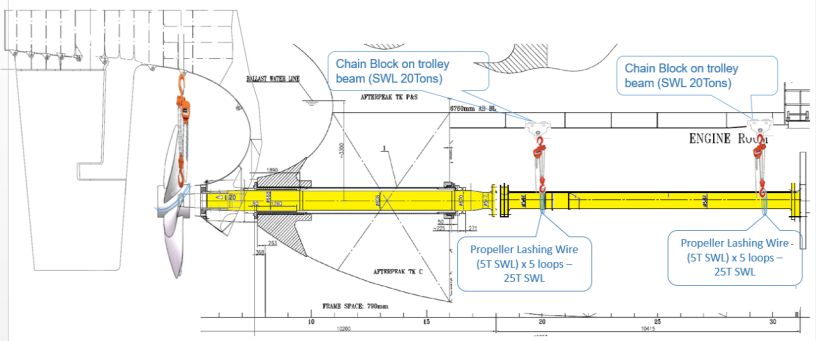

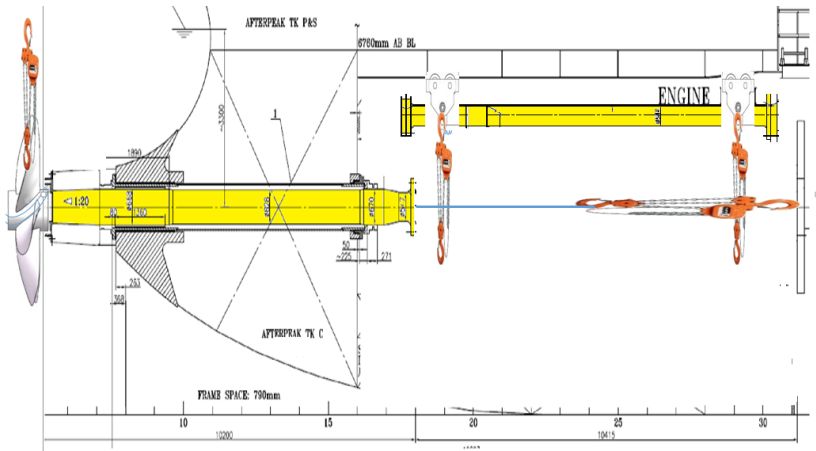

Intermediate shaft rigging arrangement

- Extract the (fwd and aft) coupling bolts with sleeves using hydraulic jacks and install four nos of service bolts at each flange to temporarily hold the shaft.

- Lash up and Hook up the trolley chain blocks onto the intermediate shaft and secure it as per the attached lifting arrangement.

- Slowly remove the service bolts and keep adjusting the chain blocks to assist in removing bolts.

- Once the service bolts are removed, lift the shaft using the chain blocks according to the arrangement.

CE 2.9

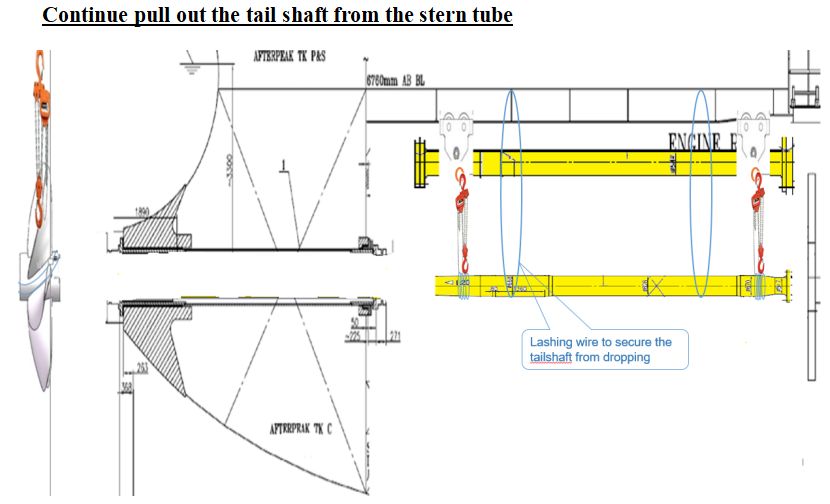

- Install an 8-ton eyebolt on the tail shaft and hook up a chain block on the flywheel using lashing wires.

- Slowly use the forward chain block and pull 1/4 of the tail shaft.

Lash up the tail shaft and hook up to the aft trolley chain block to support the weight of the post vertically.

CE 2.10

After the withdrawal of the propeller shaft, I requested the vessel superintendent and the class surveyor to witness the MPI test (Magnaflux test). An approved QA personnel performed the test. The person's competency and the equipment test certificate must be produced in front of the surveyor.

The communication flow/emergency preparedness during the lifting process is as follows.

Access Control

Access control was managed by KSL HSE and KSL Machinery Lead led by KSL Project Manager in their respective areas on the ground. Only authorized personnel identified by green vests are allowed to enter the lifting operation vicinity and carry out related works concerning the lifting operation. Watchmen were deployed to prevent unauthorized personnel from trespassing.

SUMMARY

2.12

I was able to adapt my engineering skills to projects in times of problems and failures in a successful manner, which was highly appreciated. The project helped me a lot as professionally as well as in enhancing my skills in management through manpower deployment and scheduling of the tasks as per priority.

Are you struggling to keep up with the demands of your academic journey? Don't worry, we've got your back! Exam Question Bank is your trusted partner in achieving academic excellence for all kind of technical and non-technical subjects.

Our comprehensive range of academic services is designed to cater to students at every level. Whether you're a high school student, a college undergraduate, or pursuing advanced studies, we have the expertise and resources to support you.

To connect with expert and ask your query click here Exam Question Bank