Logistics Operation Management Level 5

Learner confirmation:

I declare that this assessment is all my work, and this submission has not, in part or whole, been knowingly submitted elsewhere for review*.

- where the submission includes work from a previous assessment, this has been identified.

- where materials have been used from other sources, it has been appropriately recognised.

If this statement is untrue, I acknowledge that an assessment offence has been committed.

By signing (typing) this submission sheet, I, the learner, have read and understood all the above

*If you are selecting Approved Prior Learning as the Assessment Method, please ensure your submission meets the guidelines detailed within the IoSCM Assessment Methods guide.

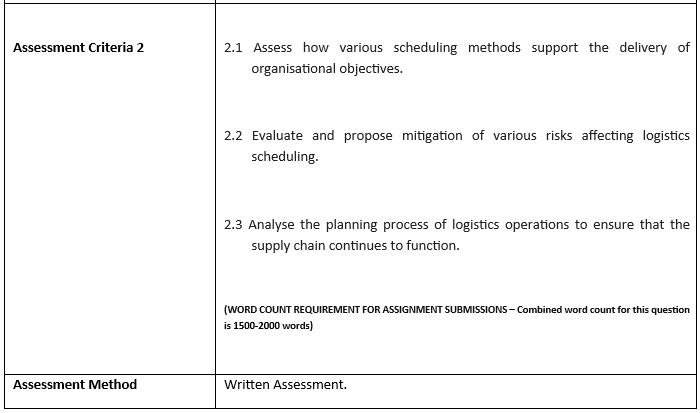

Assessment Criteria 1;

Explain how logistics operations support the delivery of customer requirements.

1.2 Consider the changes and developments to supply chains that affect logistics operations.

1.3 Summarise legislation that applies to logistics operations.

Assessment Criteria 2;

2.1 Assess how various scheduling methods support the delivery of organisational objectives.

When creating the timetable, the planner prioritises the locations with the greatest distances. The remaining drops in that pigeon-hole, which are quite close, plus the drops that are easily made en route via or to the depot are then used to make up the whole load (Pournader et al., 2020). These drops are easily selectable because of the pigeonhole system's geographic format. When a load planner uses a system like this, creating the proper routes with the depot as the centre of operations is simple and leads to effective vehicle routing on a daily basis.

Manual Scheduling:

Manual scheduling in supply chain management refers to creating production plans and schedules by hand utilising human expertise and judgement. Customer demand, production time, capacity, setup time, prioritisation, inventory management, risk assessment, and resource allocation are just a few of the variables that are included in the process. Although manual approaches are more customisable and flexible, they include drawbacks like the possibility of human error and lengthy computations (Huang et al., 2023). Notwithstanding these drawbacks, sensible decision-making in conjunction with human judgement is still essential for efficient supply chain design and implementation.

Computerised Scheduling:

The development of comprehensive concepts for managing SC networks was spurred by the intensifying rivalry in international markets and the ongoing progress in communication technology. "A set of approaches utilised to efficiently integrate suppliers, manufacturers, warehouses, and stores, so that merchandise is produced and distributed at the right quantities, to the right locations, and at the right time, in order to minimise systemwide costs while satisfying service level requirements" is how supply chain management is defined in this particular context. The scheduling literature has long addressed scheduling algorithms and their application to supply chain planning (Xu et al., 2020). This paper provides background information about production planning and scheduling functionality in commercial supply chain planning software, as well as intriguing scheduling coordination problems in supply chain planning for researchers, based on examples and experience with such software. First, we give a summary of the various planning tasks involved in supply chain planning, keeping in mind the features already included in software for supply chain planning that is sold commercially.

Supply chain management is revolutionised by computerised scheduling, which makes use of automation and sophisticated software. Organisations can easily track products, keep an eye on inventories, and handle shipments with real-time insight. Allocating resources efficiently maximises output, lowers error rates, and guarantees on-time delivery. Sales, operations planning, demand forecasting, production scheduling, and supplier collaboration are all integrated through holistic techniques. The amounts that suppliers provide can be fixed, varied within predetermined parameters, or even chosen freely. This is referred to as supplier flexibility. A system's dependability and lead time can both be used to assess its provider (Xu et al., 2020). The life cycles of the products that need to be purchased affect their quality and obsolescence, making them important to consider while organising reverse logistics. Second, the type of production that SCs use can be used to describe them. It is feasible to organise the manufacturing process in several ways (e.g., job shop problems or flow shop problems). Mass production, batch production, and one-of-a-kind manufacturing can be distinguished based on the repetition of activities, and the aforementioned classification affects setup times and costs. Autonomous planning is made possible by artificial intelligence and machine learning, which improves productivity and decision-making. In conclusion, computerised scheduling enables businesses to precisely and nimbly accomplish their supply chain goals.

2.2 Evaluate and propose mitigation of various risks affecting logistics scheduling.

The transfer of goods was impacted by labour shortages, travel restrictions, and lockdowns that interrupted transportation networks. There were operational limitations for ports, warehouses, and distribution centers. The unexpected increase in demand for some goods (medical supplies, home office equipment, etc.) put a strain on logistics, leading to delays and imbalances. Choke points in supply chains were produced by manufacturing plants closing unexpectedly and border bottlenecks. Social distancing policies and quarantines affected the availability of labour, which had an influence on last-mile delivery and warehousing operations.

Having a risk management strategy in place is also essential to guarantee prompt action in the event of an unforeseen circumstance. An organisation can take the required steps, including diversifying its suppliers, creating backup plans, or creating contingency plans, once it is aware of the possible risks in its supply chain (Wren, 2022). To reduce the risk of an unexpected disruption, for example, the organisation can build connections with many suppliers by recognising the risks associated with a particular source. In a similar vein, realising the dangers of extended lead times may encourage the company to make inventory investments and set up alternate production plans.

PESTLE Analysis:

POLITICAL:

Government Policies: Trade agreements, cross-border travel, and logistical rules are all impacted by political actions. For example: Brexit added border controls and customs processes between the UK and the EU caused port delays that affected logistical planning. Businesses have to deal with shifting international relations that affect supply chains, such as China's assertiveness and the war between Russia and Ukraine. Keep up with political developments. Increase the diversity of the distribution networks and suppliers to lessen the dependence on any one area.

ECONOMIC:

The state of the economy affects pricing, demand, and transportation expenses. Exchange rates for currencies that changes in currencies affect the cost of logistics. Businesses modify their inventory control and sourcing tactics in response to changes in the economy. Strategies for Mitigation protect business from exchange risk. Sustain financial stability to withstand disruptions to the economy.

SOCIAL:

Demands for logistics are shaped by social trends. The pandemic hastened the expansion of e-commerce, which has an impact on last-mile delivery projections. Customers are looking for greener and healthier products which leads to sustainability. Keeping an eye on customer preferences. Make last-mile deliveries more suited to evolving lifestyles.

TECHNOLOGY:

Supply chain efficiency is driven by technology through automation and visibility. IoT sensors: tracking cargo conditions in real-time. Plan ahead for setbacks and streamline operations. Investing in technology to enhance supply chain visibility is one mitigation strategy. Work together with tech-savvy logistics associates.

LEGAL:

Contracts, intellectual property, and customs are governed by legal frameworks. Compliance with new regulations for post-Brexit customs. Standards for food Compliance with laws in food distribution networks. Keeping abreast on the law. Making sure that the entire supply chain is compliant.

ENVIRONMENT:

Decisions about logistics are impacted by environmental factors. Selecting eco-friendly means of transportation. Utilise and recycle materials. Adopting environmentally friendly habits. Evaluate how logistics decisions affect the environment.

In summary, supply chain management is a dynamic field that requires resilience, adaptation, and strategic foresight. Geopolitical tensions and the COVID-19 epidemic have highlighted the importance of adaptive logistics scheduling in light of recent global events. Organisations may effectively manage these difficulties and guarantee the smooth movement of commodities across borders by adopting technology, broadening their supplier base, and remaining aware of political and economic developments.

2.3 Analyse the planning process of logistics operations to ensure that the supply chain continues to function.

There are numerous levels of planning as well as numerous functional areas, and businesses typically update their plans once a year. However, planning is and ought to be a continuous endeavour. In order to ensure that the functional plans function and serve the broader corporate plan and objectives, it is also crucial to fit them all together.

The best businesses use logistics planning are those that manufacture tangible goods and distribute them via a complex supply chain. Retail establishments, warehouses, and factories, for instance, can all enhance operations to build a more dependable and effective business that is prepared for expansion in the future.

Demand Forecasting:

Forecasting or projecting product demand is a method in supply chain management that guarantees product availability and customer satisfaction. Finding the right balance between having enough inventory to meet client demands and avoiding having an excess is the aim. Demand can be impacted by a wide range of circumstances, such as movements in the labour force, changes in the economy, extreme weather, natural disasters, or world crises (Kot et al., 2020). Smaller businesses stand a better chance of competing in the evolving market when they create logistics strategy.

Supply Planning:

Logistics optimisation refers to the strategic management of inventory, warehousing, and transportation procedures in order to guarantee the seamless flow of goods from suppliers to consumers. Supply chain planning streamlines the production and distribution of commodities from suppliers to customers, as well as from raw materials to completed goods. In essence, it's a demand-driven effort to strike a balance between excess and scarcity.

Inventory Management:

The portion of supply chain management known as inventory management organises, carries out, and regulates the storage, forward, and reverse movement of products, services, and related data between the point of origin and the point of consumption in order to satisfy customer demands. "The ongoing process of planning, organising, and controlling inventory that aims at minimising the investment in inventory while balancing supply and demand" is the definition of inventory management.

Resilient supply networks are essential, as seen by recent events like the COVID-19 pandemic, Brexit, and geopolitical concerns. To properly handle interruptions, organisations need to strike a balance between flexibility and efficiency (Monroe, 2012). Logistics scheduling, supply planning, and demand planning are all related. Cross-functional cooperation is necessary to balance supply and demand. Safety stock, often known as buffer stocks, serve as buffers against fluctuations in the supply. Spreading out where sourcing occurs lowers exposure to risk. Continuous improvement is guided by performance measures. Critical metrics include supply chain costs, inventory turnover, and flawless order fulfilment. In conclusion, supply chain management is a dynamic field that calls for cooperation, agility, and vision. Through the use of resilience, inventory optimisation, and technological utilisation, organisations may prosper in a constantly changing global environment.

Are you struggling to keep up with the demands of your academic journey? Don't worry, we've got your back!

Exam Question Bank is your trusted partner in achieving academic excellence for all kind of technical and non-technical subjects. Our comprehensive range of academic services is designed to cater to students at every level. Whether you're a high school student, a college undergraduate, or pursuing advanced studies, we have the expertise and resources to support you.