MECH 40132/60132: Advanced Manufacturing Processes Assignment

- Subject Code :

MECH-40132-60132

- Country :

Australia

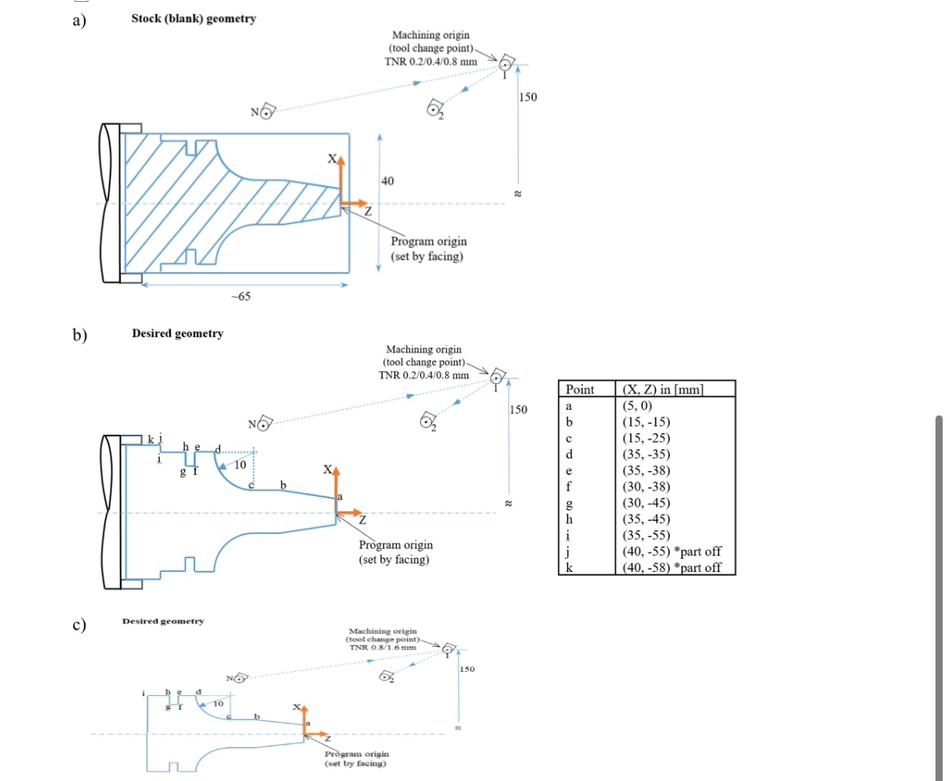

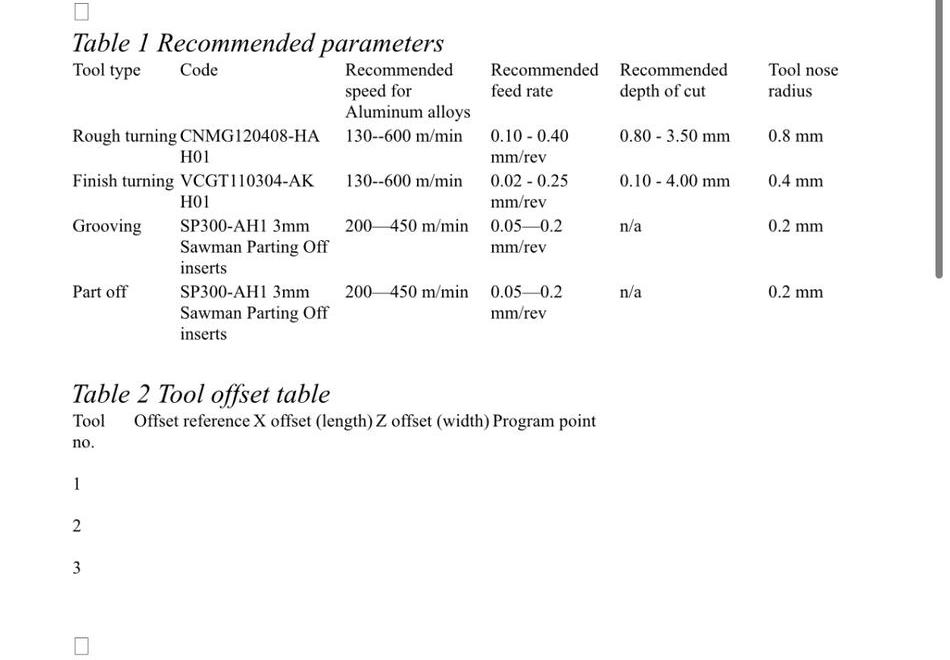

This lab session aims to program a sequence of CNC turning operations to machine the stock in Figure la as shown in Figure 1b, and get the desired shape in Figure 1c. Facing (face end), rough turn OD (outer diameter), finish turn OD, groove OD and parting off operations should be planned, and a table will be formed. The geometry of the available inserts and their recommended cutting conditions (depth of cut, cutting speed and feed rate) are given in Table 1. The target is to program the rough turning OD in multiple passes, and the finish turning OD in a single pass. Other programs (facing, grooving and parting off) may be single or multiple pass operations. Workpiece material is Al6082-T6511 (Aluminum alloy). The CNC turning centre is HAAS ST-10Y, with the maximum spindle speed of 6,000 rev/min.

Your report should include the following:

(i) Give a picture of the machine tool (can be from the web or a taken photoduring the lab session), and label the following components: Spindle, headstock, tailstock, front turret, rear turret, tool holder, cutting tool.

(ii) By the help of a sketch (that you can cite in a resource), explain the procedure to measure the tool offset by Q-setter method. Fill in the tool offset tablegiven in Table 2. How do you decide the program points?

(iii)Fill in the operations sheet given in Table 3. Give enough details so that the operator will be able to follow the procedure with no doubts.

(iv)For the rough turning OD cycle, using the maximum recommended depth of cut, how many passes will there be in total? Write the word address program for the first two passes of rough turning OD cycle. Show the tool locations in a figure, and label and match them with the corresponding G-code line. Do not use the TNR compensation with the chosen program point (be careful to leave enough distance for its activation, and remember to disable it when retracting). Include all the necessary tool change, tool offset, set spindle speed (or cutting speed), set feed rate, etc. commands. Explain each line by comments.

(v) Write the word address program for the finish turning OD cycle. Show the tool locations in a figure, and label and match with the corresponding G-code line. Use the TNR compensation (be careful to leave enough distance for its activation). Include all the necessary tool change, tool offset, set spindle speed (or cutting speed), set feed rate, etc. commands. Explain each line by comments.

(vi) Discuss the advantages of TNR compensation. In summary, your report should contain four figures showing the CNC turning center components, the Q-setter method, the rough turning tool path (for all passes), and the finish turning tool path, two tables for the operations sheet and the offsets, and a maximum of two pages of text for the roughing and finishing G-code lines and for discussing determining the program points and importance of TNR compensation. If you prefer, work in groups of two and prepare one report. Your report should be submitted in 7 days by 6 pm.